Reviews: 2021 Vol: 13 Issue: 3

3D and 4D Printing: A Review on Current Developments and Pharmaceuticals Applications

Nikita Naidu, Sagar Trivedi, Kamlesh Wadher* and Milind Umekar

Department of Pharmaceutics, Smt. Kishoritai Bhoyar College of Pharmacy, Kamptee Nagpur, Maharashtra, India 441002

Abstract

Recent years mark the rapid evolution of 3/4-Dimensional printing technologies in pharma and biomedical sector with a huge potential in the dosage form designing and personalization of the medication. 3DP is a method to produce three dimensional objects using a computer aided design from digital models by depositing excipients in successive layers. 4 Dimensional printing is a unique concept which involves the same concept as that of 3 Dimensional printing with additional time as the fourth dimension, allowing printed articles to change their shape and morphology. Using smart polymers these products alter their shape by external stimuli such as light, pH, temperature, water etc. Recently with the use of such smart polymers and printing techniques we can make printed objects which can change its shape with time as a fourth dimension. In the present article, we have focused on different types of the smart materials or the stimuli responsive materials that are used for 4 Dimensional printing of the objects followed by their applications in the Pharmaceutical and biomedical field for the delivery of the drugs, dosage form designing, tissue engineering, stents development and personalized medications. We are sure that after solving the regulatory constraints associated with 4 Dimensional printing technology it could be the next technological revolution in the pharmaceutical arena.

Keywords

Personalized medicine; 4 Dimensional printing technology; Pharmaceutical application; Additive manufacturing; Biomedical application.

Introduction

The current era is becoming more modernized due to the progressive advancements in different core of science and technology. 4-Dimensional printing (4DP) is a new paragon in additive manufacturing technique and is found to be the most remarkable transformation in the already existing 3-Dimensional printing (3DP) and conventional manufacturability. Traditional 3DP can develop complex structures of the product in single step but was unable to generate products with smart features.

3DP technology has a great application in the pharmaceutical sector but only focuses on manufacturing of static structures by using single material [1,2].This material cannot fulfill all the demands needed for the dynamic function required in pharmaceutical applications. With the progress of the biomedical Nano-technology various researches have worked on the smart-polymers also known as the stimuli responsive materials which were beneficial in the development of the drug delivery systems. The smart or stimuli responsive materials are the tactful materials which have the characteristic feature to show response when specific external stimulus is applied. These materials have the unique feature of showing pre-programmed responses and are therefore extremely suitable for the intelligent applications [3].

The external stimulus which shows the shape deformation of the smart materials includes temperature, current, magnetic energy, ultraviolet light and humidity [4]. The deformation occurred by these stimulus has shown great role in pharmaceutical development. Basically, 4DP is an incorporation of a fourth dimension of ‘time’ into the already used 3DP technique. Researcher Skylar Tibbits firstly coined the term ‘4D printing’ [5,6].

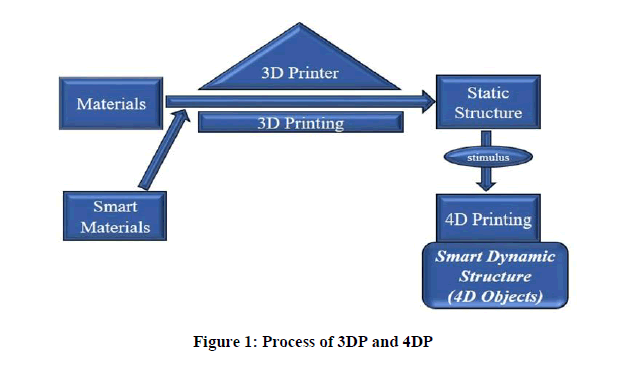

In 4DP technique, the printed product can show shape deformation because of the smart material used in the manufacturing process and are triggered by applying specific external stimulus with respect to time. Earlier 4DP was defined as ‘3DP+time’ because only with respect to time the shape of the object can be changed. But later it was found that other parameters (the shape, the function and the properties) of the printed object can also be changed with respect to time on applying the external stimuli [7]. The basic process is shown in Figure 1.

Literature Review

Awad has reported that 3DP technology is used a lot for the discovery and development of drugs and with the progress of time this technology can lead to betterment through all aspects such as energy consumption, reduction of labour which ultimately leads to reduction in cost [8].

Trenfield has also revealed that the use of smart drugs and smart materials can provide with better targeted therapy and transition to 4DP might lead to much more advancement for the delivery of drug [9].4DP is an enhancing technique, which is promising its role in different departments, such as chemistry, engineering, medical science, material sciences and computer science etc. [10,11].

4DP has also shown a remarkable advancement in Pharmaceutical and medical field. It is used in Dosage form design, development of delivery systems; chemotherapy, organ and tissue engineering, as well as various medical devices are made like stent, biomedical splint, and orthodontic devices [12,13]

In this review, we will discuss the recent developments and applications of 4DP in Pharmaceutical sector along with the risk associated and the future aspects of the technique in the Pharma and biomedical field. The work presented or developed by this technology is still in its infancy and has yet not reached humans.

4D Printing

Although the basic process involved in 3DP and 4DP are similar that is product designing by 3D modeling programs, and then printing the design with a 3D printer. The only variation in 4D printed products is the use of the smart materials and to form the adaptable design [14].

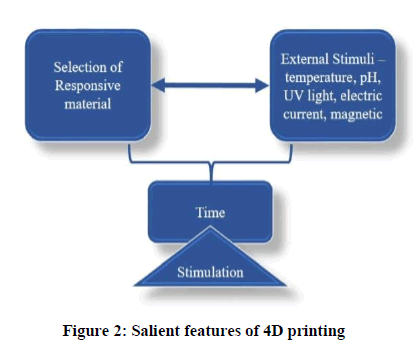

There are three main features of 4DP which must be satisfied as shown in Figure 2. The very first one is the selection of composite materials that should be responsive to the external stimuli added on it. The second one includes the external stimuli added on the material which makes the object animated. The external stimuli may be Temperature, pH, Electric current, Light etc. The third feature is the time required for the object to get simulated [15].

Recent advancement in polymer science have evolved numeral smart materials for functional 4DP, that selfassemble or deform in response to temperature, UV light, Moisture, Magnetic and electric current [5,16,17]

Smart Materials for 4D Printing

Thermo-responsive materials:Thermo-responsive materials involve the ‘Shape memory effect’ and ‘shape change effect’. As shape memory effect means after showing deformation in shape the object gets back to its original shape; whereas shape change effect means after showing deformation in shape the object changes itself to another shape which is pre-programmed [18,19]This shape deformation of the object occurs when particular heat and mechanical treatments, above the glass transition temperatures are provided and then cooled back to be fixed at a temporary shape [18] Sponchioni has reported that thermo-responsive materials have a wide application for the delivery of controlled release drugs and tissue engineering [20].

Photo-responsive materials or light responsive materials: In photo-responsive material or light responsive materials, light acts as indirect stimuli because it gets converted to heat and then shows its response to light. Liu has made a sequential self-folding polymer sheets which shows light-responsive nature [21]. Light-responsive self -assembled nanoparticles were also developed. This preparation can be used as a drug carrier and from the in-vitro drug release profile of this preparation it was found that the drug can be held at a specific site because of the light as control stimuli [22]. A visible light responsive material having high density is used for the controlled in vivo release of the insulin [23].

Moisture responsive materials: Moisture responsive materials absorb or release moisture because of the change in relative humidity and causes deformation [24]. Hydrogels are the most often used moisture-responsive material and their hydrophilic leads to more expansion of the material in comparison to the initial volume. Hydrogels as a material has high printability and are biocompatible [25]. Mao has 3D printed hydrogel and shape morphing polymer as a stimuli responsive materials. The swelling property of the hydrogel was used to drive the shape deformation and the time factor of the shape deformation was controlled by the shape morphing polymer. This occurrence between the two; leads to the shape changing effect of the material [26].

Electro-responsive materials: The current is used as an indirect stimulus for the electro-responsive materials to show the electro-responsive nature. Miriyev have printed an artificial soft muscle. They have used ethanol and silicone elastomer where after applying current, the current gets converted to heat and this heat causes the ethanol to evaporate. This leads to the expansion of the matrix because of the phase-shifting occurred from liquid to gas [27] Imdad in their research showed that, electro-simulative gels can be used for different medical purpose such as artificial muscles, actuators, sensors, lenses, as biomedical and soft material [28].

Magneto-responsive materials: Magneto-responsive materials are those materials which respond to the magnetic field. Magnetic responsive materials are the polymeric networks which physically or chemically are functionalized with the magnetic nanoparticles that have magnetic elements, like iron, Cobalt, nickel or their oxides [29] Breger have introduced magnetic nanoparticles in the printed hydrogels micro-gripper. These act as a remote for controlling the magnetic material by applying magnetic field [30].

pH responsive materials: The pH responsive polymers show response to the specific pH which can be used as trigger for the delivery of drug. The pH responsive polymers are used based on the different pH values of the different organs like the stomach, intestine. For example, 5-Fluorouracil was made for colon specific targeting by coating Eudragit S100 with citrus pectin nanoparticles [31] the polymers poly (ε-caprolactone) (PCL), poly (N, Ndiethylaminoethyl methacrylate) (PDEA) and poly (2-methacryloyloxyethyl phosphorylcholine) (PMPC), were used with three different combinations. PCL-ss-P (DEA-r-MPC) (SDRM), PCL-ss-PDEA-b-PMPC (SDBM) and PCLPDEA- ssPMPC (DSM) has been confirmed for its structure by different analytical performance. It was found that these structures are appropriate for the delivery of drugs, blood circulation, and cellular uptake of carriers, stability of the system formed for delivery [32]

Various techniques used in 3D/4D printing: Both 3D and 4D printing utilize the same technology based on Printing-Based Inkjet Systems, Nozzle-Based Deposition Systems and Laser based writing system as shown in Table 1.

| Sr. No. | 3D/4D Printing techniques | Principle | Mechanism | Application | Reference |

|---|---|---|---|---|---|

| 1 | Laser Based Writing Systems | ||||

| 1.1 | Stereo lithography (SLA) | SLA is based on the polymerization of photopolymers (resins) which are cured by ultraviolet light. | This process of printing includes the specially designed 3D printing machine, which is called as the stereo lithograph apparatus (SLA) that converts the liquid into solid 3D objects. | Bio printing of human organs, Dentistry, neurosurgery, plastic and reconstructive surgery spine surgery, and for novel methods of drug delivery micro needles. | [33-36] |

| 1.2 | Selective laser sintering (SLS) | SLS involves the laser sintering of a powdered material. This is a subdivision of “powder bed fusion”, in which the powdered material is fused by some directed energy source. | In SLS, the laser is directed for drawing a specified pattern onto the surface of the powder bed. As soon as the first layer is completed, on top of this a new layer of powder is distributed with the help of a roller. | Orally disintegrating tablets of paracetamol with hydroxypropylmethylcellulose, kollidon® VA 64 and Candurin® gold sheen was formulated by using the SLS technology. | [37,38] |

| 2 | Nozzle-Based Deposition System | ||||

| 2.1 | Fused Deposition Modelling (FDM) | FDM works on the additive principle of heating the materials and thus use of specified thermoplastic polymers. | This is a process in which a filament of desired material is prepared, and then the melted material is impelled through a nozzle to develop the desired product. | Capsular devices, Nose mask/patch, Hollow cylinder, Drug delivery devices, Liquid capsule, films, tablets. Example-fast dissolving films of square and round mesh sized, were made of ibuprofen and paracetamol. | [39-41] |

| 2.2 | Pressure-Assisted Micro syringes (PAM) | This is another nozzle-based deposition system for semisolids. | This technology is based on the use of a syringe extruder for depositing material, using a pressurized air piston, layer by layer | PAM technology is widely used for printing scaffolds of soft tissues and manufacturing of complex drug products. | [39-41] |

| 3 | Ink-Based Printing Technology: Inkjet Printing (IJP) | ||||

| 3.1 | Continuous inkjet printing (CIJ) | CIJ is based on the formation and placement of the digitally managed droplets on the substrate. | CIJ uses pressurized flow for producing a continuous stream of the droplets. The droplets are charged after exiting the nozzle and directed by the electrostatic plates to substrate or waste for recirculation. | Tablets, printlets, micro particles, microdots and different drug delivery devices. Example– with the formulation of oro-dispersable film, the possibility to formulate fixed dose have been prospected by preparing enalapril maleate and hydrochlorothiazide | [42] |

| 3.2 | Drop-on-demand (DOD) printing | DOD is based on the formation and placement of the digitally managed droplets on the substrate. The basic printing principle remains same for all types of IJP. | DOD technique holds multiple heads nearly 100-1000 and utilizes thermal head and piezoelectric crystal as a translator. | Tablets, printlets, micro particles, microdots and different drug delivery devices. Example-honey comb geometrical tablets were formulated by using beeswax (carrier) and fenofibrate (drug). |

[43,44] |

Table 1: The Various techniques used in 3D/4D printing

Smart polymers: Various smart materials are used for the development of different drug delivery systems/implants. Some of the smart polymers used recently for the development of printed dosage form or drug delivery system with 3D/4D technique used are shown in Table 2.

| Sr. no. | Smart polymer/materials | 3D/4D printing technique used | Formulation/drug delivery system | Reference |

|---|---|---|---|---|

| 1 | Polyvinyl alcohol (PVA) | 3D printer | Printed tablets-2015 | [45] |

| 2 | Polyvinyl alcohol (PVA) | Fused deposition 3D printing | Extended release dosage form (2015) | [46] |

| 3 | Polylactic acid | 3D printer Fused deposition 3D printing | Biofilm disk-2016 | [47] |

| 4 | Poly(lactide-co-glycolide) (PLGA) and Polycaprolactone (PCL) | Extrusion-based 3D printer | Patches-2016 | [48] |

| 5 | Polylactic filament | Fused Deposition Modeling | Oral solid dosage form-2017 | [49] |

| 6 | Eudragit RL 100/Poly (e-caprolactone) | fused deposition modelling | 3D printed tablets loaded with polymeric nanocapsules-2017 | [50] |

| 7 | Eudragit RL filament and polyvinyl alcohol (PVA) | Fused Deposition Modelling | bilayer dosage form-2018 | [51] |

| 8 | Poly L-lactic acid | Stereolithography strategy | Drug delivery Implants-2019 | [52] |

| 9 | Poly(lactic-co-glycolic acid) (PLGA) and polyethylene glycol (PEG) | 3D printer | PLGA films, PLGA–PEG–PLGA discs-2020 | [53] |

| 10 | Polylactic acid (PLA) filament | fused deposition modeling 3D printer | Capsular device-2020 | [54] |

Table 2: Smart polymers used in 4D printing

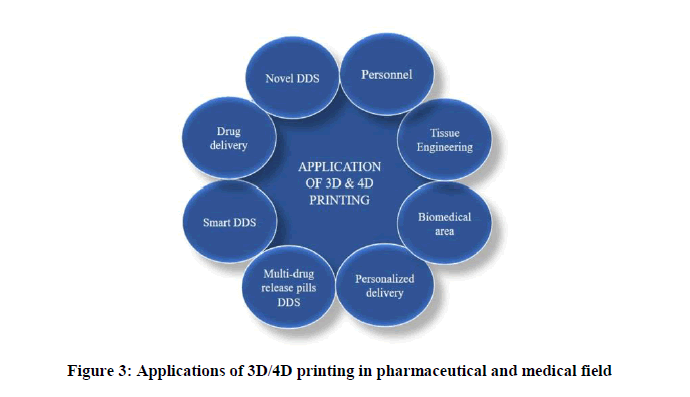

Applications of 4D printing in pharmaceutical and medical development: The innovative emergence of smart polymers and technology in 4D printing has definitely enhanced its applications in the pharmaceutical and medical field as depicted in Figure 3 [55].

4DP has a wide application in healthcare, which ranges from nanoparticle design to tissue engineering to manufacture of human scale biomaterials [56] in medical field; we have the requirement for the medical implants and devices which are made as per the patient specific requirement to the body. So 4DP can definitely fulfill the requirement as the implants fabricated can change the shape with respect to time in the body [57,58] Thus the implants are manufactured by 4D printing technology and are implemented in the patients which make surgery easy and are patient specific [13,59]

4D printed hydrogels: The evolution of 4D printed bio-devices is expanding the demand of 4D printing in the biomedical field. The 4DP of the hydrogel composite structure was found to align cellulose fibrils which mimic the plant movements and behaved as a shape-morphing device. 4DP of hygroscopic materials is utilized for the accurate sensing [60,61]. Nano-composites have intensified the 4DP technology by providing excellent shape stability after printing the product. A 4D printed hydrogel was developed by in situ polymerization of the acrylamide in agarose matrix containing the laponite. It was reported that laponite shows excellent thixotropy and also shape stability after the printing, the mechanical properties were also found to be improved [62].

As shape memory polymers can show change in shape when external stimuli is applied and are used in biomedical field because of its biodegradability and also shape memory effects. A bio-designed tracheal scaffold was 4D printed by using SMP and this has shown superior fixation results in comparisons to the traditional tracheal scaffolds [63] the materials or polymers having shape morphing effect are used for wound healing. The wound dressing were found to be suitable, compatible, and degradable in body. Silk fibroins a dressing are non-immunogenic, highly absorbs water, permeable to air, degrade lately and are also cheap are therefore excellent to be used as a wound healing product [64].

Drug delivery: Recently 4DP has shown wide application for the delivery of the drugs. The 4D printed indwelling devices for the drug delivery to the intravesical region were made and the shape memory polymers which show water solubility and also shape regaining to water at body temperature were involved. These can be administered in an acceptable provisional shape by the use of catheter. Later they recover the original shape and are retained in the bladder for a period of time, then gets dissolved with time and then eliminated out through the urine. Poly (vinly alcohol) was selected for the water-induced response to occur because of its hot-process ability, availability in different molecular weights [65].

A novel shape memory expandable gastro-retentive drug delivery system (SMX GRDDS) device was formulated. The expansion of the system occurs by the combination of body temperature and contact with minimum volume of fluids. A quantitative method was used to examine the shape changes occurred in acidic environment at 37 ± 0.5 °C. A satisfactory extent of recovery in shape was observed within few minutes with respect to the previously set threshold value. Shape changes which occur on heating and mechanical deformation do not show any impact on the release performance of prepared prototypes [66].

Malachowski have reported the 4D printed drug eluting devices, developed by using thermoresponive materials. These are the therapeutic grippers which are referred as “theragrippers” and are shaped by using the photolithographic patterning. These are composed from the poly (propylene fumarate) segments and from thermoresponsive poly (N-isopropylacrylamide-co-acrylic acid) hinges. These theragrippers can be filled with some of the commercial drugs like doxorubicin and mesalamine which was released for almost 7 days. These grippers can be used for the sustained release of such drugs [67].

Daehoon have 4D printed a micro-needle which has curved barbs facing towards back side for improving the tissueadhesion, which ultimately leads to the improvement in drug delivery, bio-fluid collection and also bio-sensing [68].

Smart electro-active polymers respond under electric stimulus, and shows different biomedical applications. This polymers show applications in the delivery of drugs and also in tissue engineering, mimic muscle activity, antimicrobial activity [69].

Stents: For the manufacturing of a stent it requires different steps because of its specified and complex structure, but should be patient specific. 4DP fabricates customized stent very quickly. The shape morphing effect of this technique is a boon for the implantation of stents as invasiveness in surgery is minimized. Thus, by merging the advantages of additive manufacturing technique and morphing capability, 4DP can be found to be promising for the next-generation of personalized minimally invasive medical devices. For example, a printed stent can be deformed into a temporary shape, then inserted into the body and after implanting at correct place it regain its original size and shape due to variation in temperature [70].

A 4D printed stent was developed by Ge with the use of high resolution projection micro stereo lithography for proving the ability of manufacturing 4D printed stents and demonstrating the relevance of shape memory polymers for the manufacturing of stents [71]. Wei has 4D printed stents by using a feasible manufacturing technique which involves the ultraviolet cross-linking of PLA-based inks with magneto-responsive materials and are allowed to be guided to their destination by the magnetic remote [72].Two different types of 4D printed personalized stents were developed, they show shape morphing effect and have negative poisson's ratio. They were also evaluated for various mechanical tests, shape morphing tests and feasibility test. The stents when studied in the simulated body fluid were able to show blood vessel expandation within 5 sec, so it shows that they have a great potential for treatment of vascular stenosis [73].

Tissue engineering: In tissue engineering, cultured cells and scaffolds are used together to form tissues that are implanted in to the human body. Shape morphing polymers are used as a scaffold to incorporate newly formed tissues [74].Due to the shape changing property of the shape morphing polymers, they can be delivered to the site of injury with minimal invasion [75,76] There has been great research on the 4D bio-printing for in vitro as well as invivo applications. For the development of the functional human tissues the Organovo Holdings Inc., U.S.A has been working on different bio-printing projects. This company is working on the artificial human liver by using 4D printing technology. This technology has the capability to develop programmable biological materials with shape changing property and thus can be the basis for enabling the smart pharmacology, personalized medications and also programmable cells, tissues and organs [77,78].

Challenges: The invention of 4D printing is considered to be the game changer in the pharmaceutical manufacturing sector, there are many challenges ahead which constraints the utilization of this technology. The challenges include selection and scarcity of smart polymers, selections of the other excipients, validation of the entire process, printer selection, post processing parameters, quality control, packaging of the product, mechanical instability, shelf life, variation in product quality, reproducibility, drug and polymer compatibility, pre and post formulation studies. The health and safety concerns of the formulator is also a major concern, which need to be taken in to consideration for the hassle free use of 4DP technology Also there is regulatory issue in the process of printing the 4D dosage form since, there are no valid regulations for the design, manufacturing process, selection of excipients, and quality control of the prepared formulation [79].

Discussion and Conclusion

In recent years 4DP has shown an extraordinary advancement in different fields. 4D bio-printing is now seen as a next generation printing technique that shows manufacturing of the complex structures having shape morphing feature with respect to time on applying external stimuli. This technique has a great use of the smart materials for the development of the printed object that are used pharmaceutically.

The different smart materials or the stimuli responsive materials show changes when specific stimuli are applied on it. 4DP has a great application in the pharmaceutical field for delivery of drugs, personalized medications, smart drug delivery, development of biomedical devices and tissue engineering. The advancement in different Nanocomposites is still improving the development of printed products and enhancing its application. Thus the great potential of 4DP technique can be used to maximize its application in pharmaceutical field with great benefits. Regulatory concern of this technology is the main challenge in pharmaceutical and biomedical sector since validation and quality control are main requirement of this sector. We are sure that, after overcoming the technical and regulatory challenges 4DP technology will create niche in pharma manufacturing and drug delivery development.

References

- X Kuang, DJ Roach, J Wu, CM Hamel, Z Ding. Adv. Funct. Mater. 2019, 29(2).

- K Wadher, R Trivedi, N Wankhede, M Kale, M Umekar. Ann.Pharm.Françaises. 2020.

- MQ Zafar, H Zhao. Met. Mater. Int. 2020, 26(5), 564–585.

- YS Lui, WT Sow, LP Tan, Y Wu, Y Lai. Acta Biomater. 2019, 92, 19–36.

- S Tibbits, Archit. Des. 2014, 84 (1), 116–121

- D Raviv, W Zhao, C McKnelly, A Papadopoulou, A Kadambi, et.al Sci. Rep. 2014, 4 (1), 1–8.

- X Kuang, DJ Roach, J Wu, CM Hamel. Qi, Adv. Funct. Mater. 2019, 29(2).

- A Awad, SJ Trenfield, A Goyanes, S Gaisford, AW Basit. Drug Discov. Today. 2018, 23 (8), 1547–1555.

- SJ Trenfield, A Awad, et.al., Expert Opin. Drug Deliv. 2019, 16 (10), 1081–1094.

- GF Hu, AR Damanpack, M Bodaghi, WH Liao, SMaS. 2017, 26 (12), 125023.

- Z Ding, C Yuan, X Peng, T Wang, HJ Qi. Sci. Adv. 2017, 3 (4), e1602890.

- TH Kwok, CCL Wang, D Deng, Y Zhang, Y Chen. J Mech. Des. Trans. ASME. 2015, 137 (11).

- M Zarek, N Mansour, S Shapira, D Cohn, Macromol. Rapid Commun. 2017, 38 (2), 1600628.

- J Choi, OC Kwon, W Jo, HJ Lee, MW Moon. 3D Print. Addit. Manuf. 2015, 2 (4), 159–167.

- E Pei, Assem. Autom. 2014, 34 (4), 310–314.

- D Kokkinis, M Schaffner, AR Studart. Nat Commun. 2015, 6 (1), 1–10.

- JO Hardin, TJ Ober, AD Valentine, JA Lewis. Advanced materials 2015.

- MD Hager, S Bode, C Weber, US Schubert. Prog. Polym. Sci. 2015, 49(50), 3–33.

- Y Zhou, WM Huang, SF Kang, XL Wu. J Mech. Sci. Technol. 2015, 29 (10), 4281–4288.

- M Sponchioni, UC Palmiero, D Moscatelli. Mater. Sci. Eng. C. 2019, 102, 589–605.

- Y Liu, B Shaw, MD Dickey, J Genzer Sci. Adv. 2017, 3 (3), e1602417.

- J Pang, Z Gao, H Tan. Front. Chem. 2019, 7, 620.

- BR Sarode, K Kover, SH Friedman. Mol Pharm. 2019, 16 (11), 4677–87.

- K Zhang, A Geissler, M Standhardt. Sci Rep. 2015, 5 (1), 1–13.

- YS Zhang, K Yue, J Aleman. Ann Biomed Eng. 2017, 45 (1), 148–163.

- Y Mao, Z Ding, C Yuan, S Ai. Sci Rep. 2016, 6.

- A Miriyev, K Stack, H Lipson, Nat Commun. 2017, 8 (1), 1–8.

- I Ali, L Xudong, C Xiaoqing, J Zhiwei. Sci Eng. C. 2019, 103.

- Smart Polymers and Their Applications-2nd Edition, 2009.

- JC Breger, C Yoon, R Xiao. ACS Appl. Mater. Interfaces. 2015, 7 (5), 3398–3405.

- MB Subudhi, A Jain, A Jain. Materials (Basel). 2015, 8 (3), 832–849.

- Z Wu, Z Gan, B Chen. Biomater. Sci. 2019, 7 (8), 3190–3203.

- R Yao, G. Xu, S.S. Mao. Cancer Biol. Med. 2016, 13 (4), 443–451.

- J Wang, A Goyanes, S Gaisford, AW Basit. Int J Pharm. 2016, 503 (1-2), 207–212.

- US4575330A-Apparatus for production of three-dimensional objects by stereo lithography-Google Patents, 2008.

- A Kaza, J Rembalsky, N Roma, V Yellapu. Int Acad Med. 2018, 4 (3), 252.

- JM Williams, A Adewunmi, RM Schek. Biomaterials. 2005, 26 (23), 4817–4827.

- F Fina, CM Madla, A Goyanes, J Zhang. Int J Pharm. 2018, 541 (1-2), 101–107.

- LK Prasad, HS myth. Drug Dev. Ind. Pharm. 2016, 42 (7), 1019–1031.

- S Lamichhane, S Bashyal, T Keum. Asian J Pharm. Sci. 2019, 14 (5), 465–479.

- T Ehtezazi, M Algellay, Y Islam. J Pharm Sci. 2018, 107 (4), 1076–1085.

- Y Thabet, D Lunter, J Breitkreutz. Int J Pharm. 2018, 546 (1-2), 180–187.

- J Goole, K Amighi. Int. J. Pharm. 2016, 499 (12), 376–394.

- M Kyobula, A Adedeji, MR Alexander. J Control Release. 2017, 261: 207–215.

- A Goyanes, PR Martinez, A Buanz. Int J Pharm. 2015, 494 (2), 657–663.

- J Skowyra, K Pietrzak, MA Alhnan. Eur J Pharm Sci. 2015, 68, 11–17.

- J Boetker, JJ Water, J Aho. Eur J Pharm Sci. 2016, 90, 47–52.

- HG Yi, YJ Choi, KS Kang, JM Hong. J Control Release. 2016, 238, 231–241.

- CI Gioumouxouzis, OL Katsamenis, N Kouropoulos. J Control Release. 2017.

- RCR Beck, PS Chaves, A Goyanes. Int J Pharm. 2017, 528 (12), 268–279.

- CI Gioumouxouzis, A Baklavaridis. Eur J Pharm. Sci. 2018, 120, 40–52.

- Y Wang, L Sun, Z Mei, F Zhang. Mater Des. 2020, 186, 108336.

- I Serris, P Serris, KM Frey, H Cho, AAPS Pharm Sci Tech. 2020, 21 (7).

- HM Jeong, KY. Weon, BS Shin, S Shin. Molecules. 2020, 25(10), 2330.

- Editor’s Pick, European Medical Journal, 2008.

- F Pati, J Jang, DH Ha, S Won Kim. Nat Commun. 2014, 5(1), 1–11.

- MP Chae, DJ Hunter-Smith. J Reconstr Microsurg. 2015, 31(6), 458–463.

- Q Ge, AH Sakhaei, H Lee, CK Dunn. Sci Rep. 2016, 6.

- S Miao, N Castro, M Nowicki. Mater. Today. 2017, 20 (10), 577–591.

- KK Sadasivuni, D Ponnamma. Springer International Publishing, Cham,UK, 2019.

- D Correa, A Papadopoulou, C Guberan. 3D Print. Addit Manuf. 2015, 2 (3), 106–116.

- J Guo, R Zhang, L Zhang, X Cao, ACS Macro Lett. 2018, 7 (4), 442–446.

- W Zhao, F Zhang, J Leng, Y Liu. Compos. Sci Technol. 2019, 184, 107866.

- M Farokhi, F Mottaghitalab, Y Fatahi. Trends Biotechnol. 2018, 36 (9), 907–922.

- A Melocchi, N Inverardi, M Uboldi. Int J Pharm. 2019, 559, 299–311.

- A Melocchi, M Uboldi, N Inverardi, F Briatico-Vangosa. Int J Pharm. 2019, 571, 118700.

- K Malachowski, J Breger, HR Kwag, MO Wang. Angew. Chemie Int. 2014, 53 (31), 8045–8049.

- D Han, RS Morde, S Mariani. Adv. Funct. Mater. 2020, 30 (11), 1909197.

- H Palza, PA Zapata. Materials (Basel). 2019, 12 (2).

- K Kuribayashi, K Tsuchiya, Z You. Sci Eng. A. 2006, 419 (1-2), 131–137.

- Q Ge, AH Sakhaei, H Lee. Sci Rep. 2016, (6).

- H Wei, Q Zhang, Y Yao. ACS Appl Mater Interfaces. 2017, 9 (1), 876–883.

- C Lin, LJ Zhang, YJ Liu, LW Liu, JS Leng,Sci. China Technol Sci. 2020, 63 (4), 578–588.

- Y Wong, J Kong, LK Widjaja, SS Venkatraman, Sci China Chem. 57 (4), 2014, 476–489.

- YC Chiu, HY Fang, TT Hsu, CY Lin, MY Shie, J Endod. 2017, 43 (6), 923–929.

- CC Ho, HY Fang, B Wang, TH Huang, MY Shie, Int Endod. J. 2018, (51), e291–e300.

- J An, KC Chua, V Mironov, 2016, 2 (1), 3–5.

- ZX Khoo, JEM Teoh, Y Liu, CK Chua, S Yang, J An, KF Leong, WY Yeong, Virtual Phys. Prototyp. 2015,10 (3), 103–122.

- ZZhang, KG Demir, GX Gu, Int J Smart Nano Mater. 2019, 10 (3), 205–224.